How We Used Psycho-Aesthetics™ to Identify Unique Opportunities in the Project.

Using our proprietary Psycho-Aesthetics® 2.0 framework, we conducted in-depth interviews and ethnographic observation in diverse lab settings. We identified key emotional and usability pain points — such as intimidation with complex interfaces, workspace clutter, and trust in precision. These insights guided both the form and interface strategy, ensuring approachability and confidence in operation.

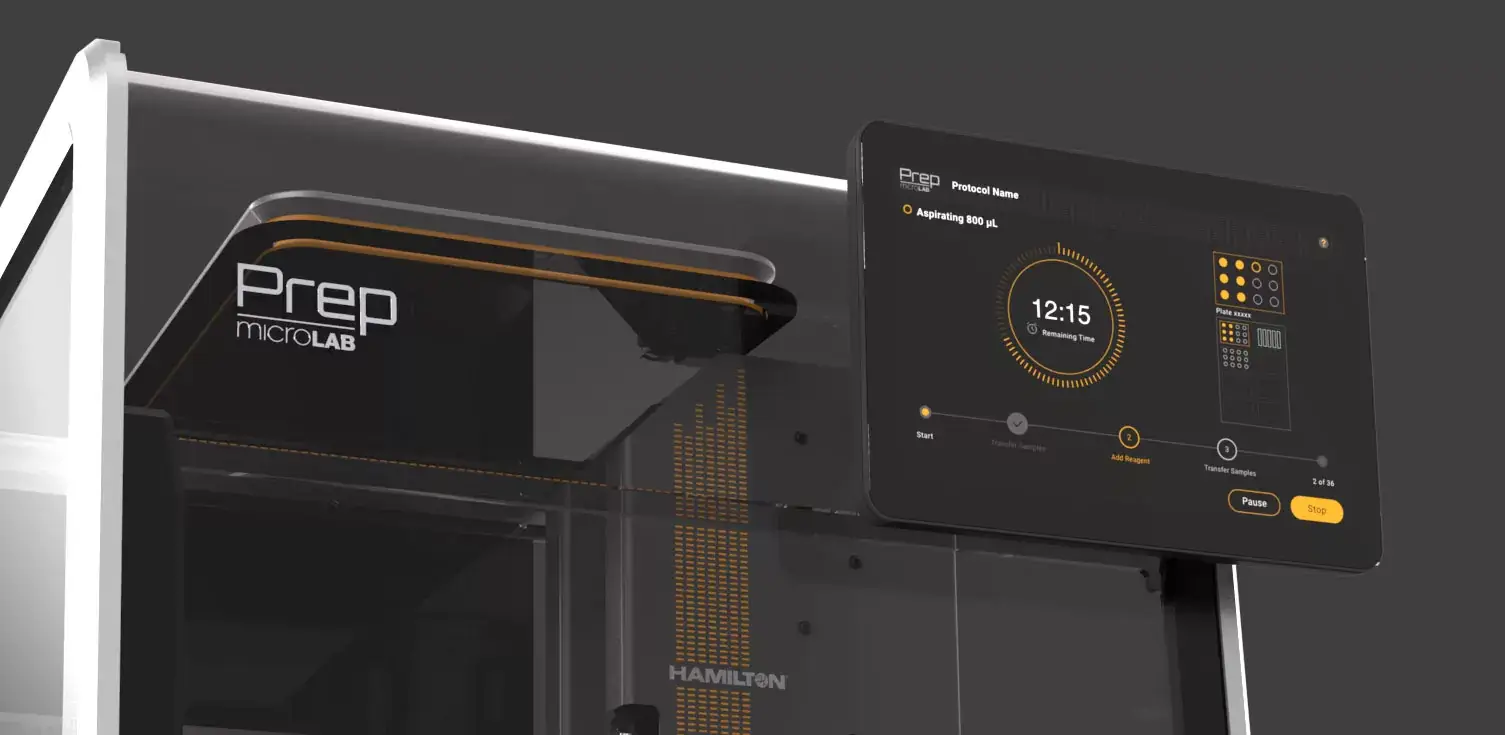

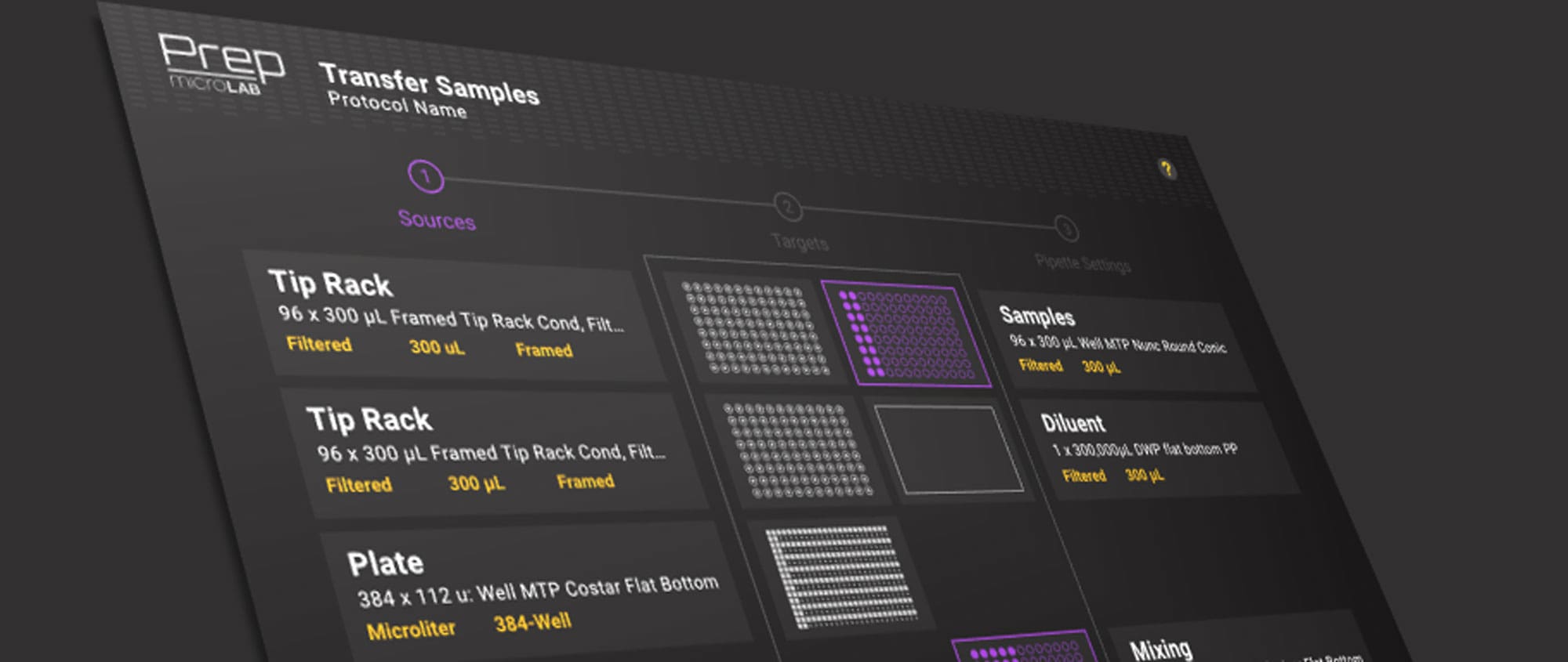

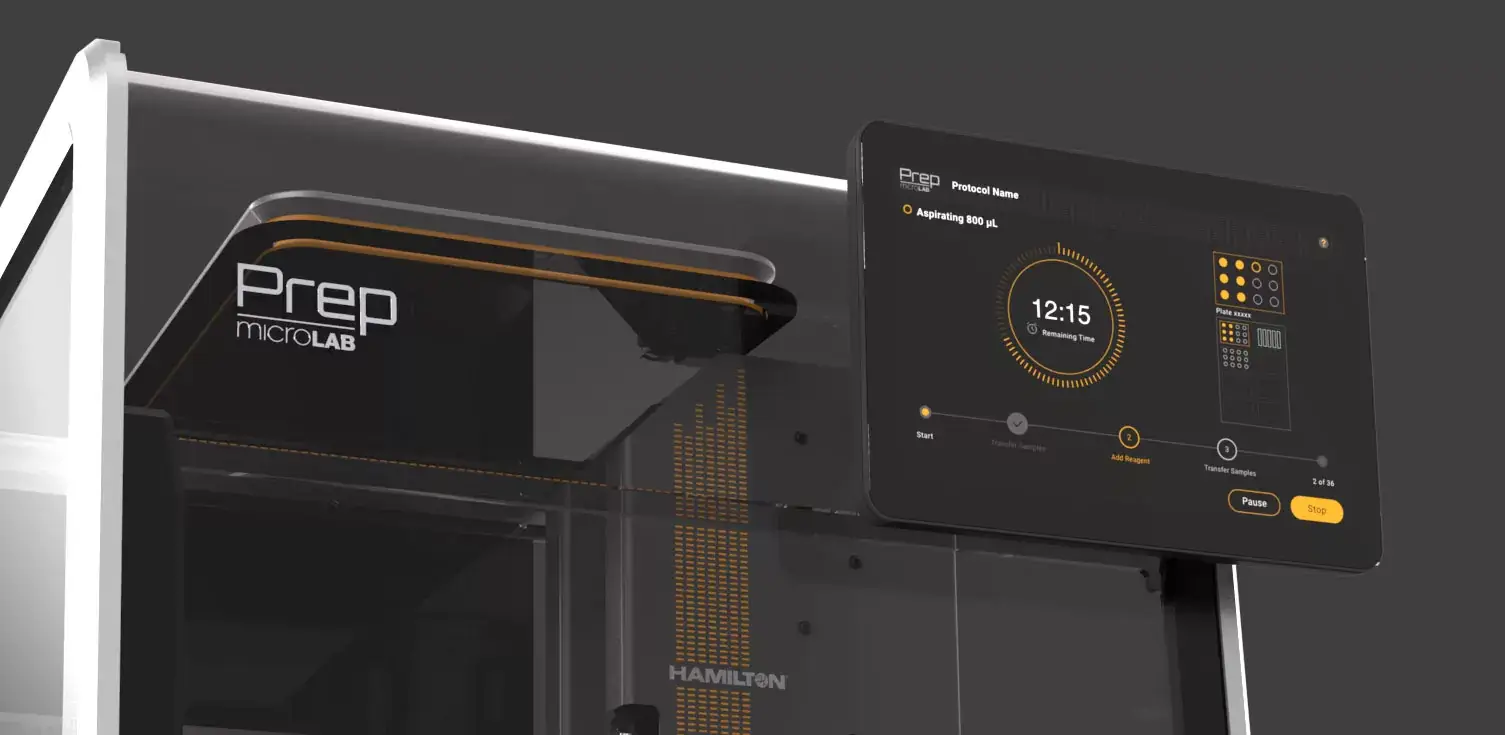

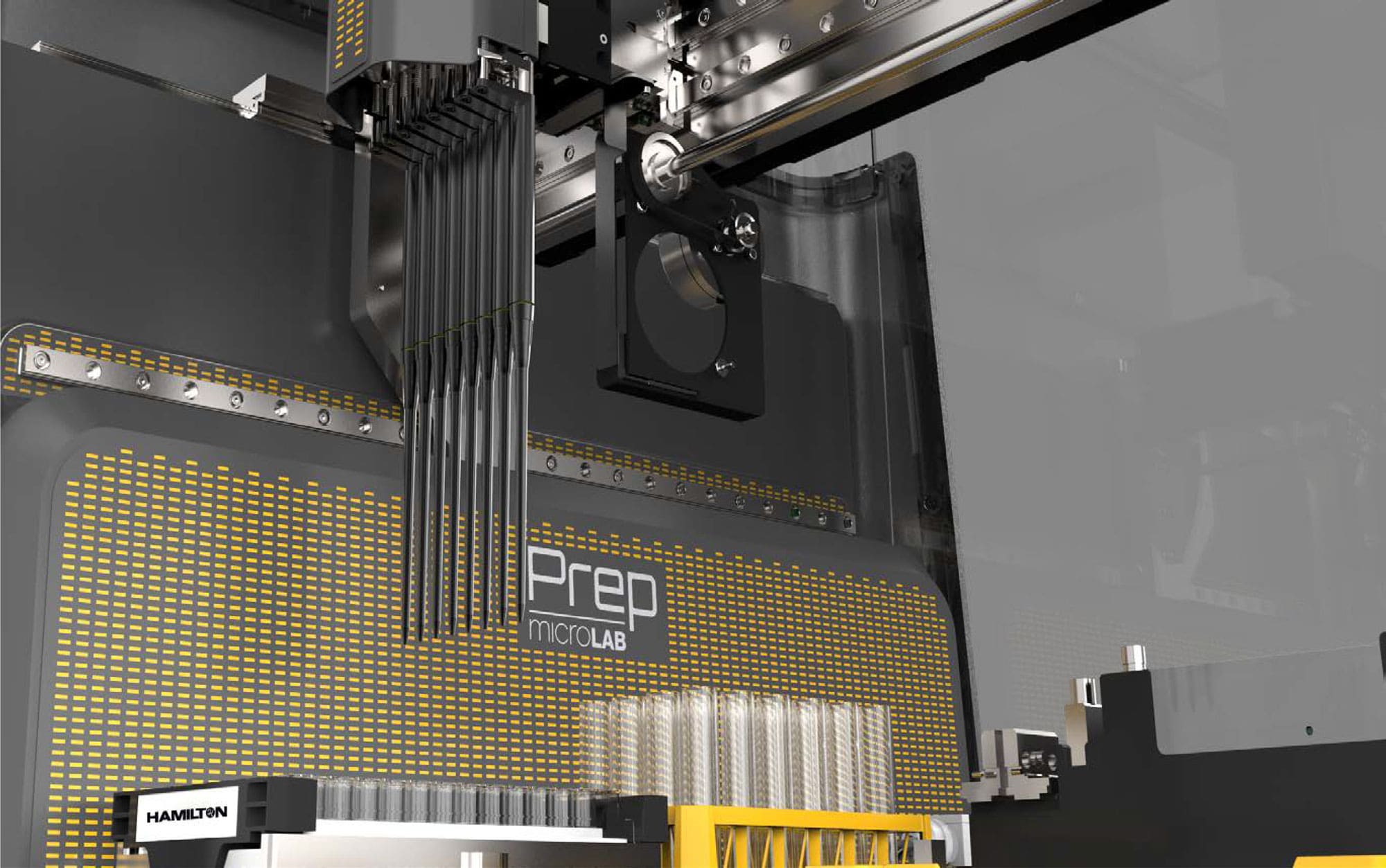

Enhanced laboratory efficiency

Reduced human errors and variability

Strategy

Welcome to a world of design and innovation

If this is not the case, then click the button below to start it