How do I hire a product development firm?

If you have found yourself asking this question, or others like this here are some other questions and answers to help guide your decision.

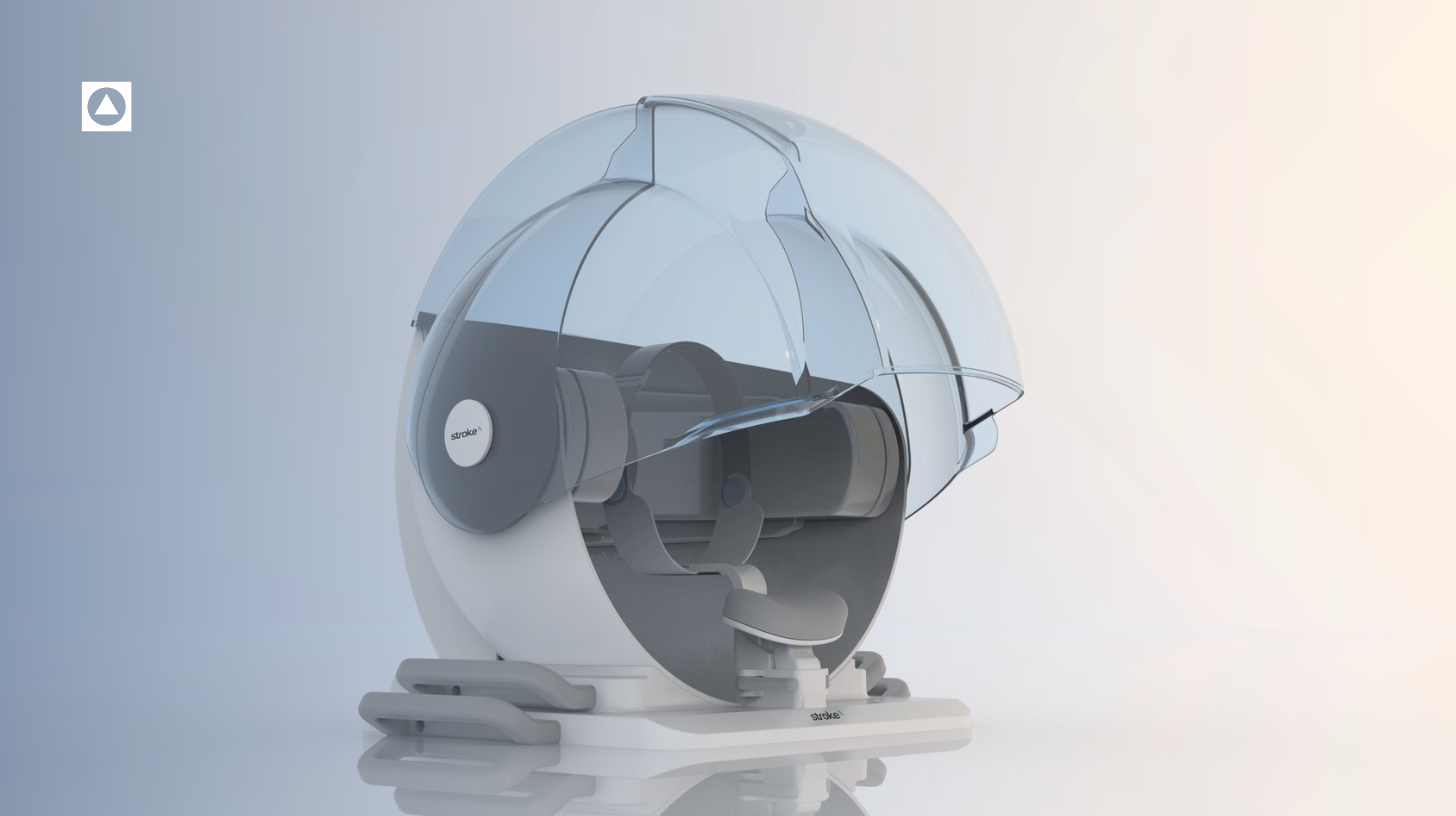

1. What are the firm's areas of expertise?

When considering hiring an industrial design firm, it’s important to understand their areas of expertise. This will ensure that the firm has the necessary skills and knowledge to tackle your project and deliver the best results. Look for firms that specialize in your specific industry or product type to ensure that they have the relevant experience.

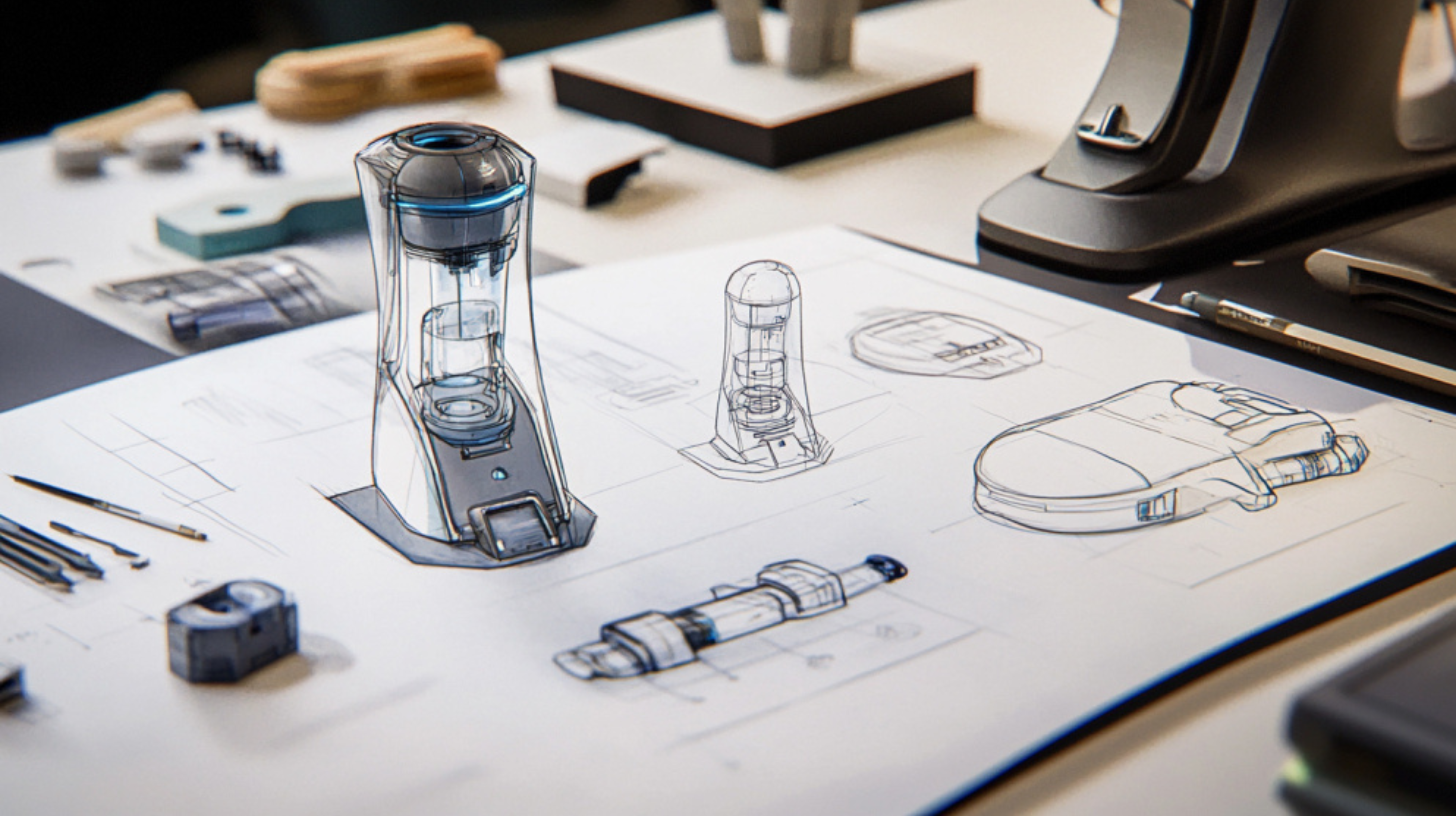

2. What is the firm's design process?

The design process is another crucial aspect to consider when hiring an industrial design firm. A well-structured design process will ensure that your project is completed efficiently and effectively. Look for firms that have a clear and organized design process that includes research, conceptualization, prototyping, and testing. This will give you confidence that the firm will deliver a high-quality product that meets your needs.

3. How does the firm handle communication and collaboration?

Communication and collaboration are key to the success of any project. When hiring an industrial design firm, make sure to ask about their communication and collaboration strategies. Look for firms that have a clear and efficient communication system in place, and that are open to feedback and input from their clients. This will ensure that the project stays on track and that you are satisfied with the final product.

4. How does the firm handle budget and timelines?

Budget and timelines are important considerations when hiring an industrial design firm. Make sure to ask about their approach to budgeting and timelines, and how they handle any unexpected delays or changes. Look for firms that are transparent and upfront about their budget and timelines, and that have a proven track record of delivering projects on time and within budget.

5. What is the firm's aproach to prototyping and manufacturing?

Prototyping and manufacturing are critical stages in the industrial design process. Make sure to ask about the firm’s approach to prototyping and manufacturing, and how they ensure that the final product meets your specifications and quality standards. Look for firms that have a proven track record of delivering high-quality prototypes and manufactured products that meet your needs and exceed your expectations.

6. Does the firm have experience working in your specific industry?

Experience working in your specific industry is a key factor to consider when hiring an industrial design firm. Look for firms that have a proven track record of delivering successful projects in your industry and are familiar with the unique challenges of your industry. This will give you confidence that they have the necessary skills and knowledge to deliver a high-quality product that meets your needs.

7. Does the firm have any certifications or awards?

Lastly, certifications and awards are another important consideration when hiring an industrial design firm. Look for firms that have been recognized by industry leaders and have received certifications or awards for their work. This will give you confidence that the firm is a reputable and reputable company with a proven track record of delivering high-quality products.

Information to Consider:

Find out if they have internal development capabilities

Not all design and engineering firms have development capabilities, and in a marketplace with so many design and engineering firms, it can be difficult to tell who do, or how much is actually implemented internally rather than farmed out. Development is the third competency that only some design and engineering firms have seasoned experience of. Depending on the project and how it has evolved from its inception , a design firm will be your product development firm, with both happening under the same roof. In our opinion, this is ideal because design firms are good at bringing a diversity of perspectives to the tasks of innovation and engineering. A Development firm that can build a team of both designers and engineers of diverse experience will create very grounded and impactful innovations and patentable solutions; and developing products around designs that are based on a sound engineering perspective, increases speed to market, product quality, customer engagement and ultimately their likelihood of success in the marketplace.Understand how they use external contractors

Because product development is a challenging cross-disciplinary effort, it’s common for design or engineering firms to rely on external companies to aid product development. Down the line, this type of collaboration usually causes issues that degrade the outcome of the project. In our experience, an outside engineering company simply isn’t going to be considering the design or the user experience when recommending engineering choices or vice versa. Development needs to be a single process between engineering and design, which requires high levels of communication and trust between the designers, engineers, and other team members. It’s worth noting that almost all development firms, even ones with design and engineering capabilities, use external contractors in some regards. Creating new technologies or using existing technologies in new ways often call for outside expertise in a limited capacity. As a result, they will have long-standing relationships that they can immediately call upon.

Determine their risk management procedures

Without clear guidelines, product development can quickly blossom from an idea into an ever-growing project that exceeds both the initial goal and the project budget. Therefore, proposals for product development should be structured around managing risk in the development process. The proposal should be thoughtful and explicit around the phases, stage gates, and critical decision points in the process. The proposal should also set up checks and balances to ensure that the budget is utilized appropriately. Tripwires can help ensure that the development stays on course, and that the team remains laser-focused on achieving the desired end results. One way we manage risk at RKS, is by developing a product requirements document. The product requirements document is a working document that establishes what the product has to have, including the major functional requirements. Establishing the product requirements document early on helps to make sure a project remains tied to key requirements.Confirm that they have vendor and manufacturing relationships

In almost all cases, products are developed to be produced and introduced into the market. This means that once development has finished, vendors will need to supply materials and components, and manufacturers will need to mass produce the product. In order to minimize tooling costs, cost of goods sold, and cost to market, vendors and contract manufacturers should be routinely integrated into the development process. Finding a firm with established relationships is the easiest way to ensure that vendors and manufacturers are integrated into the process. Another reason to find a firm with existing relationships is secure vendor supply and manufacturing allotment. Global instability has made it more challenging to find vendors and manufacturers on the fly, as many do not accept new clients or require commitments to accept new clients. In some cases, the development firm will need to help you source new vendors and manufacturers, especially if the technologies are new. Therefore, you want to find a firm that has experience of working with a variety of vendors and manufacturers, and that can find new vendors, vet vendors, or secure supply in a competitive market.