PERIMETRICS

Harnessing Percussion Diagnostics paired with Machine Learning (AI) to diagnose damage that otherwise can't be detected.

What We Did

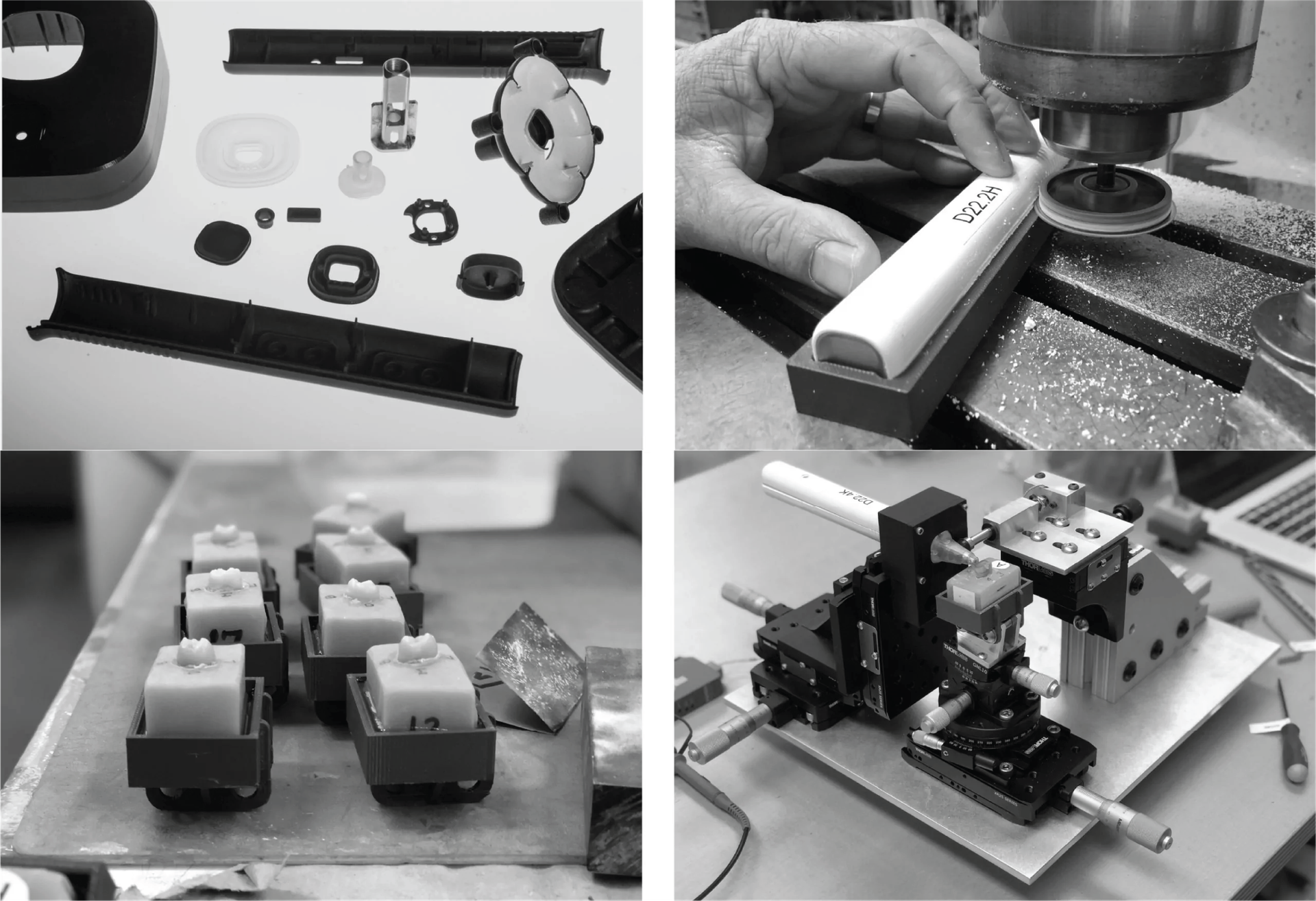

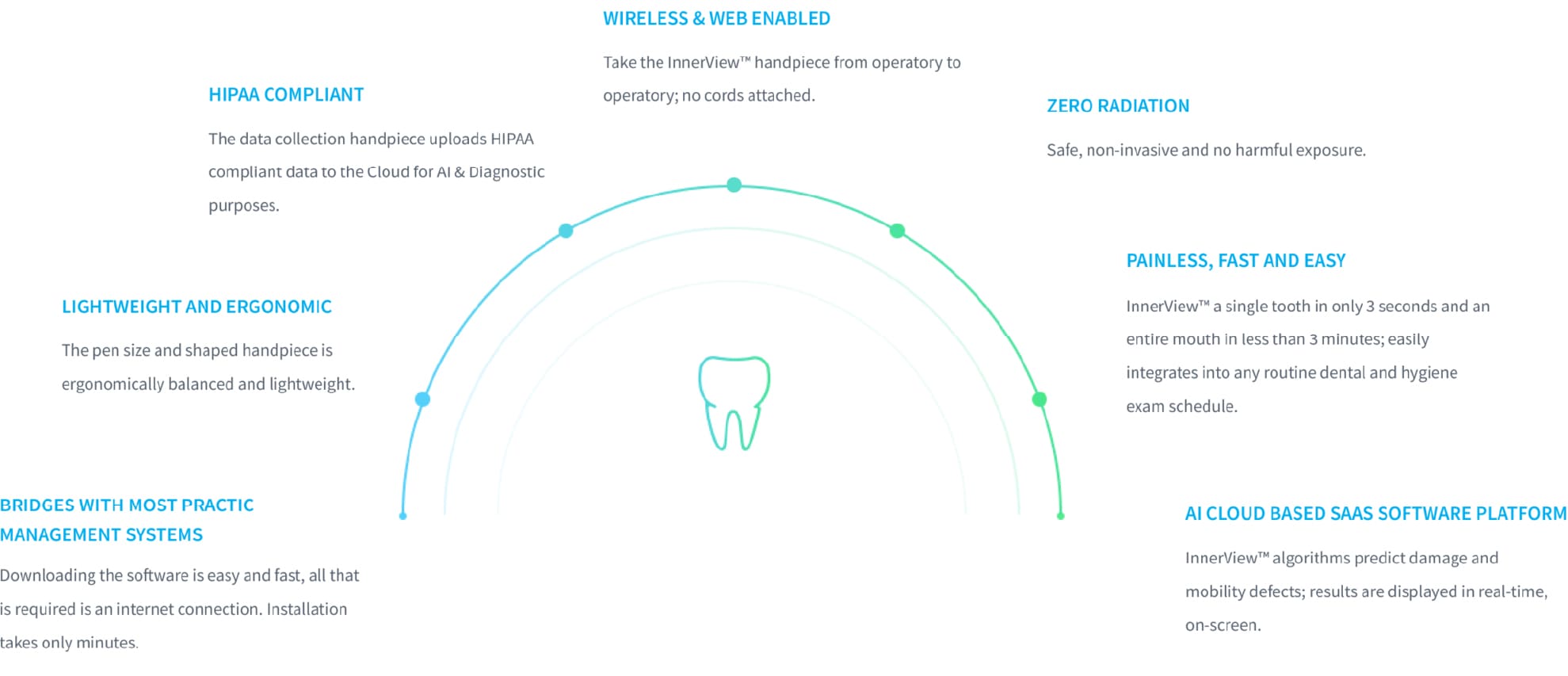

RKS innovated and developed the InnerView™ AI system to empower dentists through proprietary Quantitative Percussion Diagnostics to detect damage, mobility and overall tooth health that otherwise go undetected. The rapid measurement and diagnostic tool was a ground-up development program that involved generations of human factors and mechanical proof of concept prototypes, subsequently tested on custom-built test and measurement fixtures and in the dental office by clinicians. The RKS engineering team led the development that brought together mechanical, electronics and software engineering, together with the client’s team, to create the FDA-approved device that gives dentists and hygienists unique insights into the health of a patient’s teeth, wirelessly, via an app on the operatory computer. Applying our Psycho-Aesthetics methodology at every step, the project leveraged the full gamut of RKS’s in-house skills, covering innovation engineering, human factors, industrial design and UI/UX to develop a rapid, non-invasive, pain-free and radiation-free diagnostics procedure. This new technology empowers dentists and dental clinicians to eliminate the guesswork and provide strategic care and quantitative tooth health monitoring for their patients. RKS’s responsibilities included design for manufacture, FEA, vendor sourcing, CM and tooling management, parts inspection and quality management, batch production and assembly.

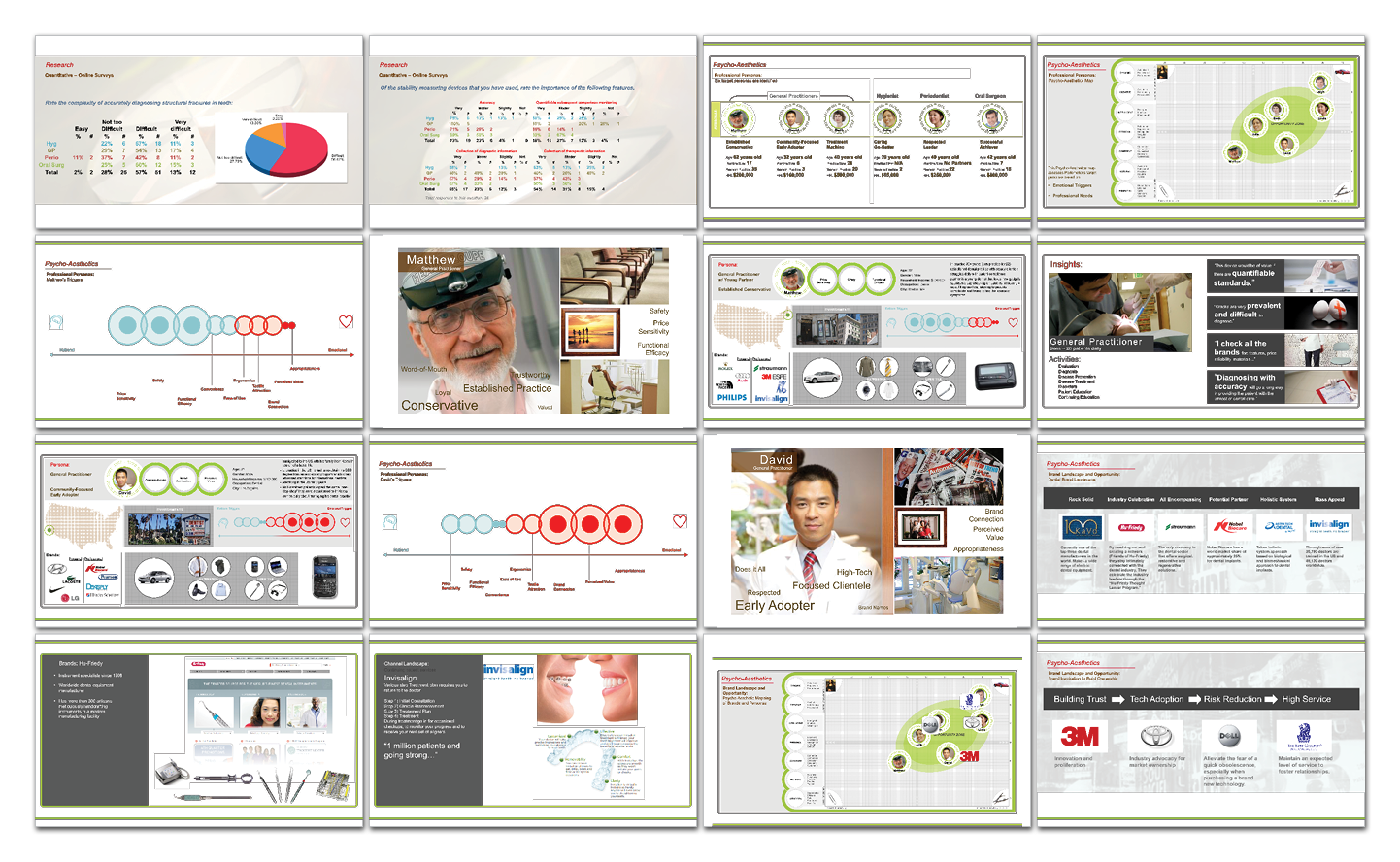

Psycho-Aesthetics™

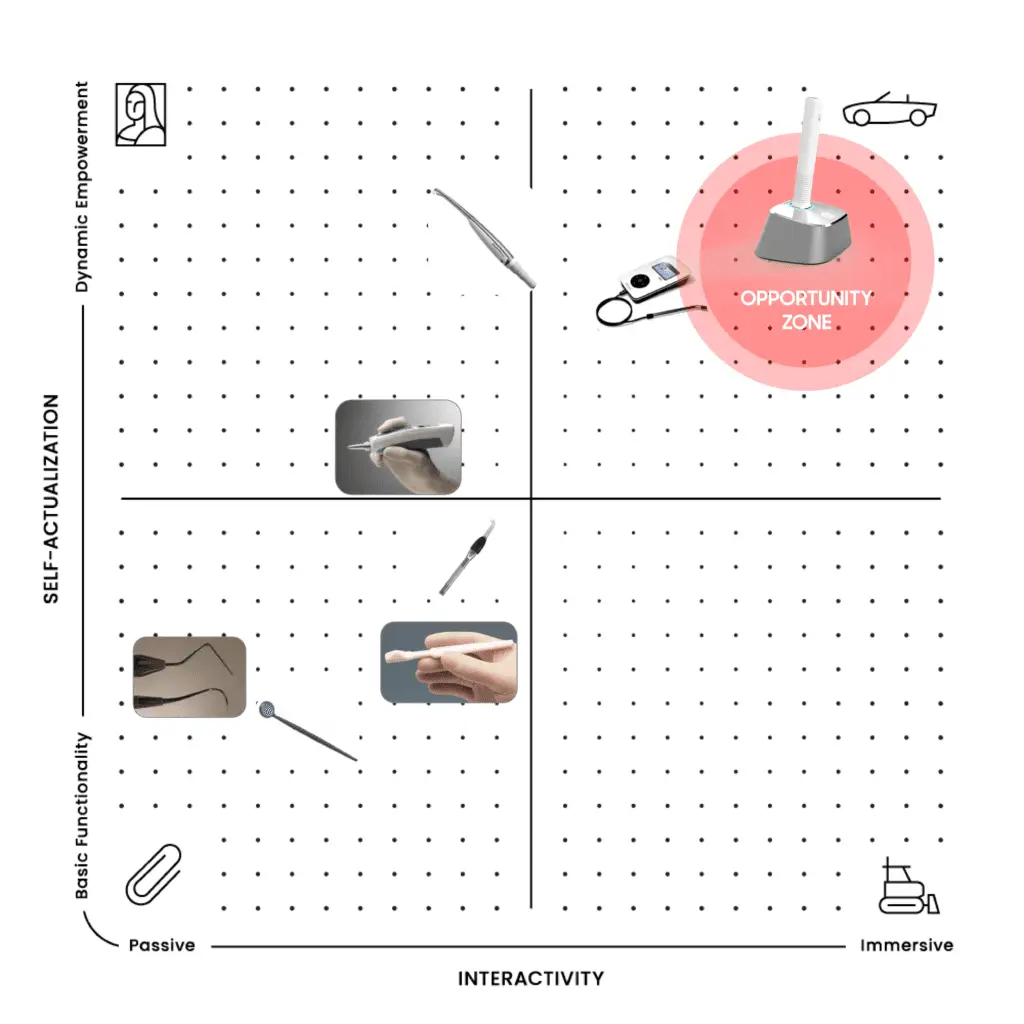

Product design is more than just winning awards; it’s about creating emotional connections between the product and the user. Our human-centered approach, Psycho-Aesthetics, helps us understand and quantify these connections. Our design firm uses it to create innovative products, technologies, services, brands, and more. We aim to create solutions that are relevant and impactful, using our approach to grow our clients’ businesses. With Psycho-Aesthetics as our foundation, we work with clients to establish a common language that can be used throughout our relationship. We found the opportunity zone for Perimetrics to be in the enriched quadrant, implementing a richer set of features and immersion for dentists. Perimetrics was designed to be the perfect combination of immersive interactivity and dynamic self-actualization.

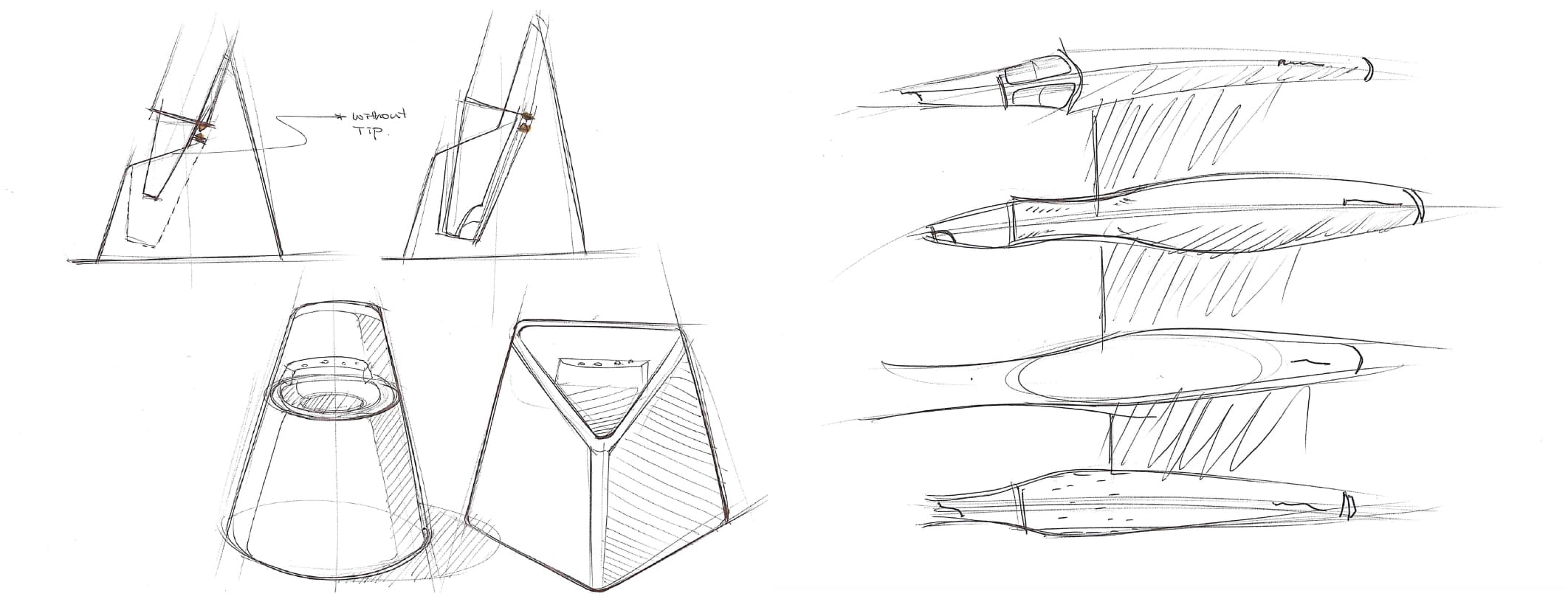

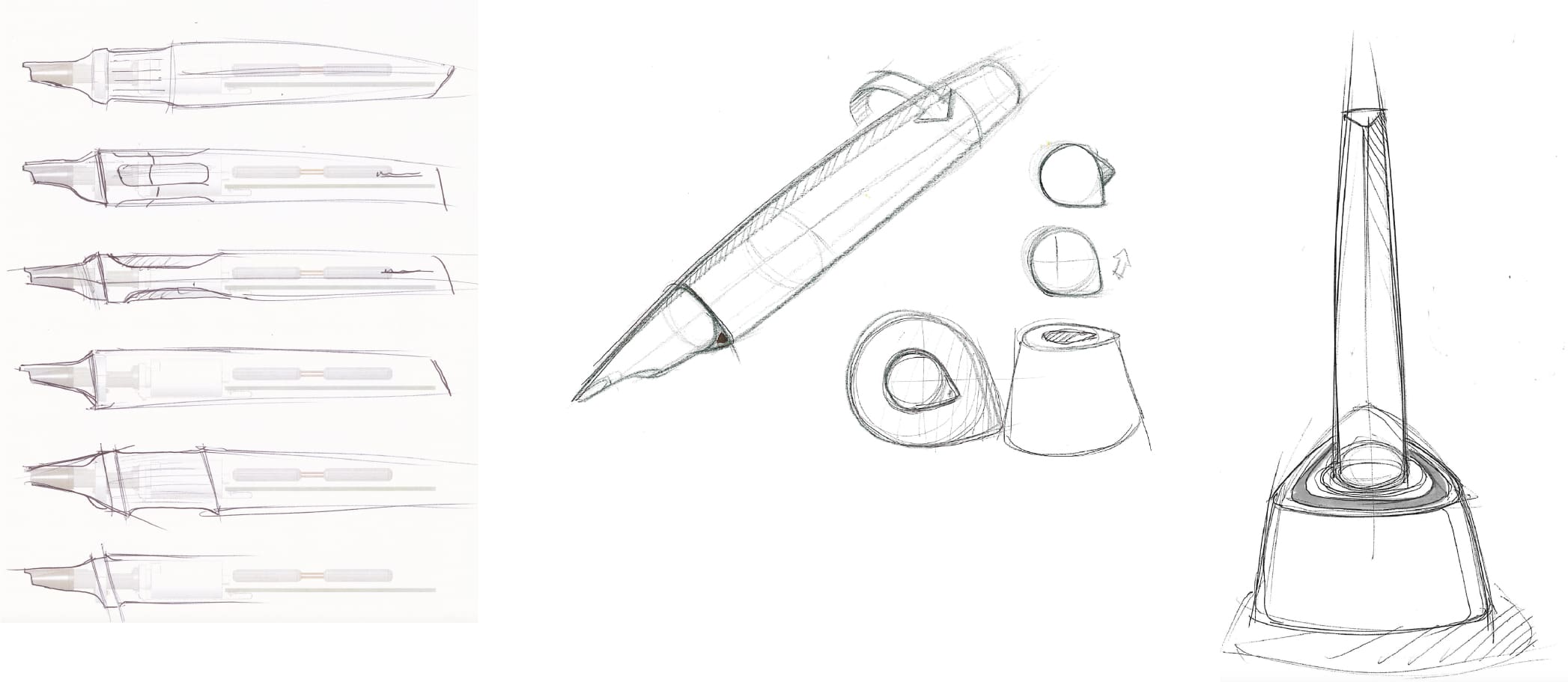

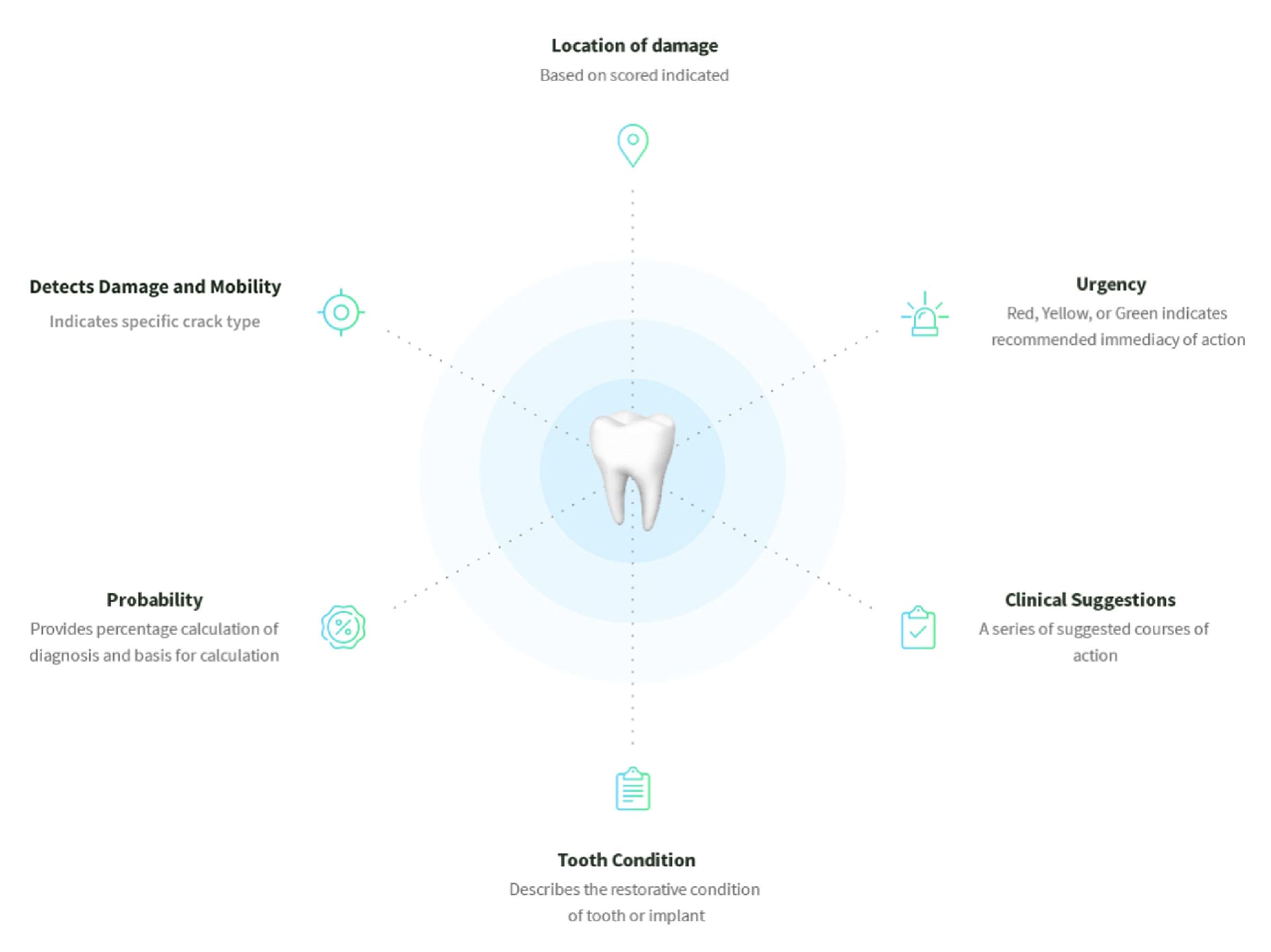

Applying our renowned Psycho-Aesthetics methodology at every step, RKS Design leveraged a wide array of in-house skills, including innovation engineering, human factors, industrial design, and UI/UX, to create a rapid, non-invasive, pain-free, and radiation-free diagnostics procedure. The InnerView™ AI system utilizes proprietary Quantitative Percussion Diagnostics (QPD™) to detect damage, mobility, and overall tooth health that would otherwise go undetected. The device’s mechanism involves gentle percussive tapping on the tooth, capturing rich data through sensors on the handpiece’s tip, and processing it in real-time using our proprietary algorithm to identify specific crack types.

With the integration of Artificial Intelligence, InnerView™ Technology is set to disrupt the dental industry by enabling clinicians to detect and diagnose invisible damage in teeth. Throughout the development process, RKS Design prioritized the fusion of industrial design and human factors, ensuring that the InnerView™ AI system was lightweight, ergonomic, and user-friendly. The handpiece’s pen-sized and shaped design offers optimal balance and comfortable handling for dental professionals. Moreover, the system seamlessly bridges with most practice management systems, enabling easy installation and integration into dental practice workflows.

This innovative diagnostic system eliminates the guesswork, providing dentists with strategic care and quantitative tooth health monitoring for their patients. RKS Design’s responsibilities extended beyond engineering and included design for manufacture, FEA analysis, vendor sourcing, CM and tooling management, parts inspection and quality management, as well as batch production and assembly.

Through a collaborative effort with the client’s team, we successfully engineered an FDA-approved device that provides dentists and hygienists with unparalleled insights into tooth health wirelessly via an operatory computer app. Through RKS Design’s expertise in industrial design and human factors, the InnerView™ AI system has revolutionized dental diagnostics, delivering exceptional results, improved patient care, and streamlined dental practices worldwide.

RKS Project Spotlight

Hamilton C6

DISCUS DENTAL

Life Tech

PERIMETRICS

What We Did

Psycho-Aesthetics

Product design is more than just winning awards; it’s about creating emotional connections between the product and the user. Our human-centered approach, Psycho-Aesthetics, helps us understand and quantify these connections. Our design firm uses it to create innovative products, technologies, services, brands, and more. We aim to create solutions that are relevant and impactful, using our approach to grow our clients’ businesses. With Psycho-Aesthetics as our foundation, we work with clients to establish a common language that can be used throughout our relationship. We found the opportunity zone for Perimetrics to be in the enriched quadrant, implementing a richer set of features and immersion for dentists. Perimetrics was designed to be the perfect combination of immersive interactivity and dynamic self-actualization.