REVA’s innovative designs and curated flavours provide high-quality, safe, and enjoyable smoking sessions for an unparalleled experience.

IGT’s transformative PeakBarTop with Sports Betting brings the bartop experience to a whole new level. The design allows a player to watch a live sporting event and make a range of wagers on comprehensive sports betting menus.

Industrial products usually face fewer regulations than consumer ones. Yet, they still need to follow health, safety, and environmental rules like TSCA, Prop 65, and EU standards like REACH. Consumers can also use some industrial designs, which then face extra regulations. If a product isn’t strictly industrial, we ensure it meets CPSC safety standards. Throughout our design process, we ensure products align with all necessary regulations and are ready for agency testing.

Industrial products need to be durable and efficient for high-intensity environments. We often design them for mass production to keep costs low. Our process considers these tough requirements and ensures designs are affordable for the market. Our designers prioritize understanding these needs from the start.

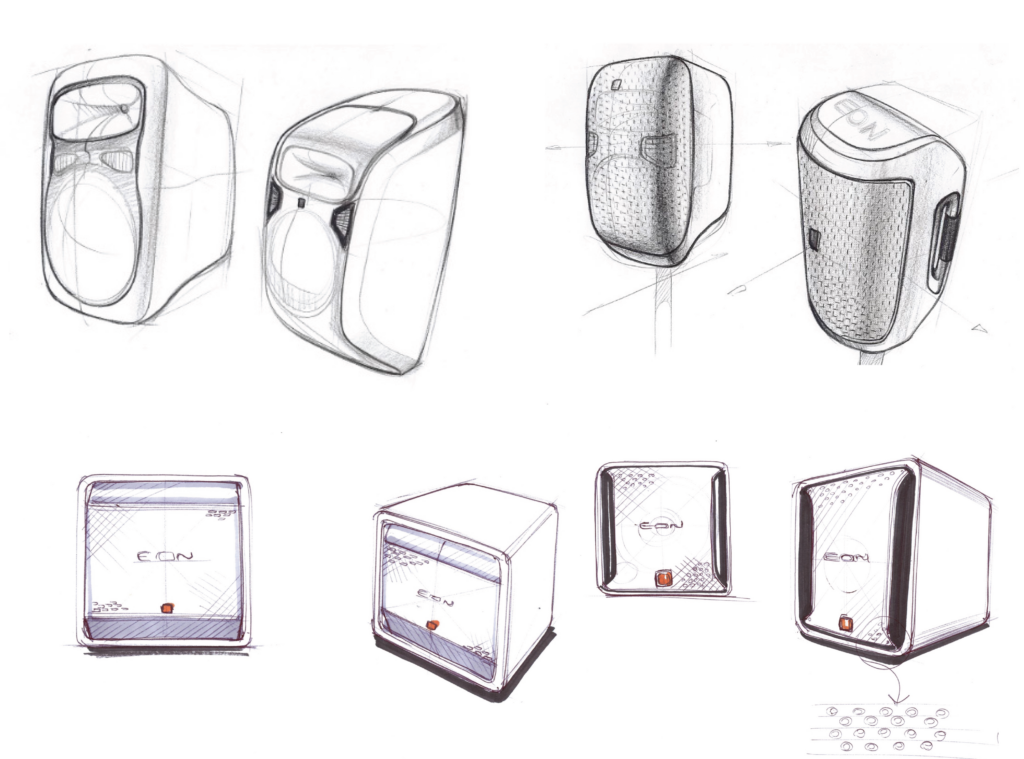

We use our special psycho-aesthetics methodology in our industrial product development process to create emotional ties between products and users. Instead of just focusing on how a product feels, we consider how it makes users feel about themselves. For industrial designs, this means helping workers feel safe and efficient. Our designs aim to reduce risks and speed up tasks. Industrial product experience design emphasizes a product’s aesthetic appeal, structural form, color palette, and tactile experience.

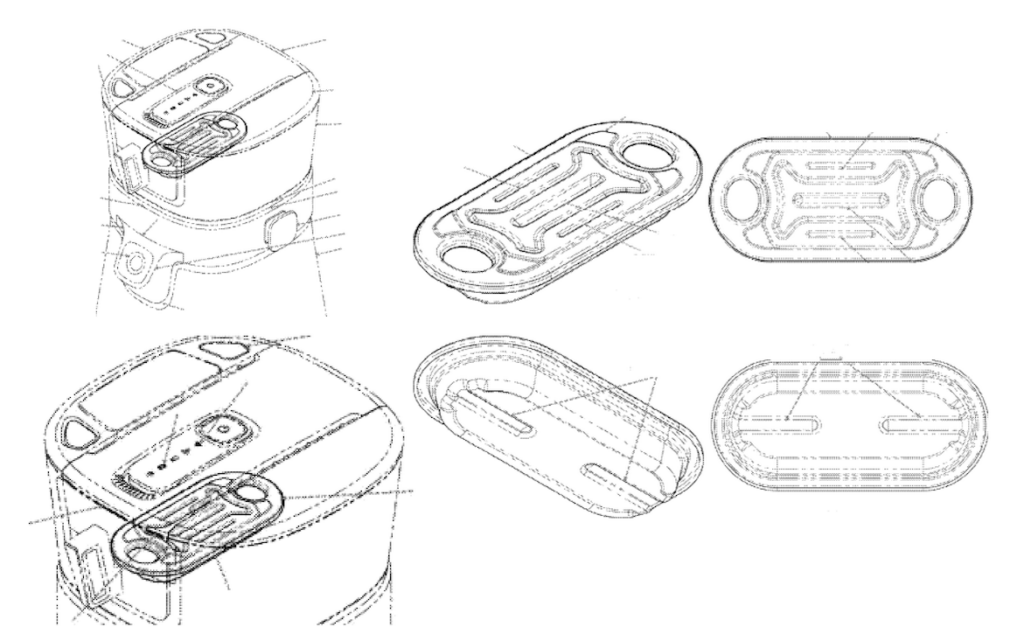

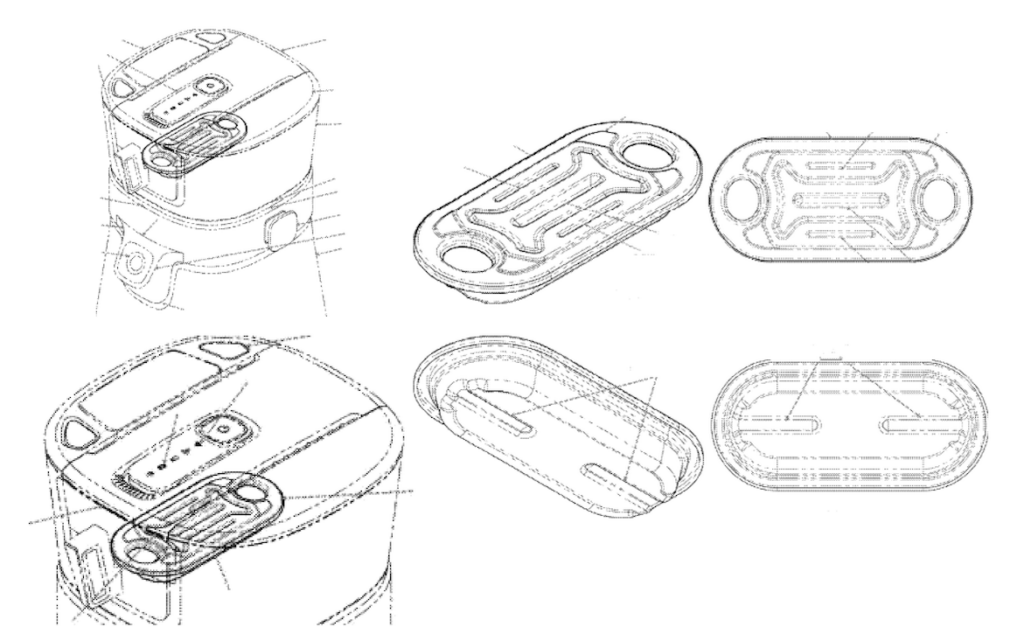

Industrial products come with specific challenges needing expert engineering. Our experienced team often designs with intricate systems and innovative materials. Using advanced AR/VR and CAD tools, we address these issues early, speeding up the design, prototyping, and production process.

We use a three-phase approach for technology roadmap development. First, we set essential requirements, leadership, and scope. Next, we pinpoint system needs, main technology areas, and alternatives. In the final phase, we refine our roadmap before implementing it. This process ensures we prioritize cost-effective technologies for outstanding results.

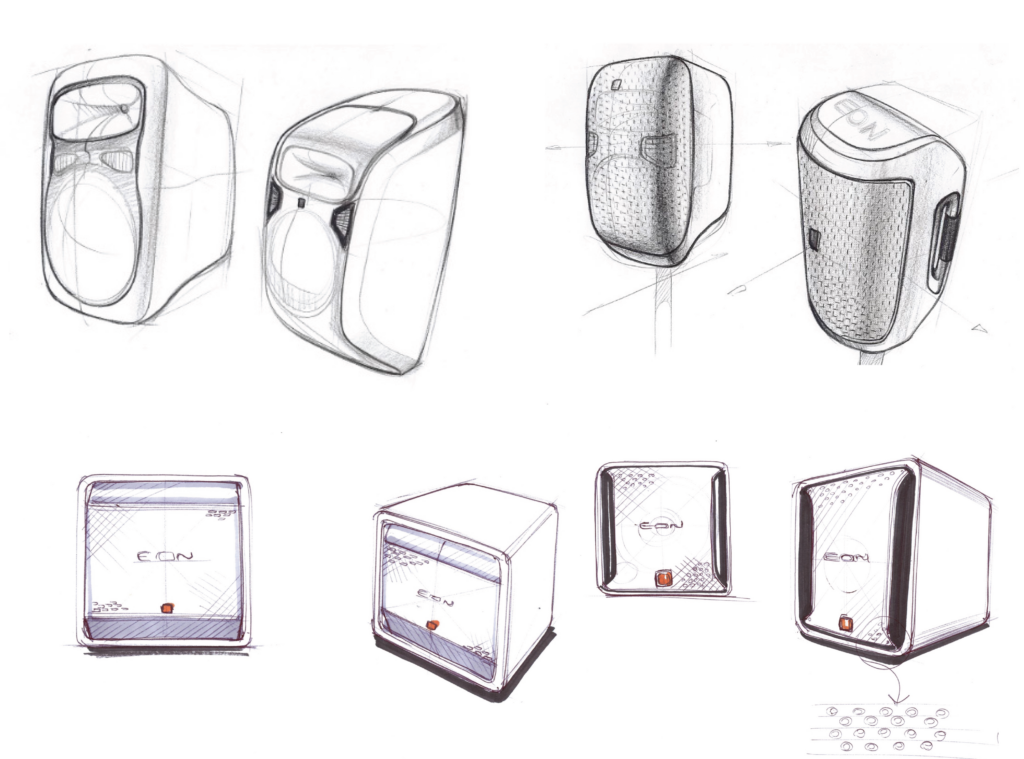

Our proof of concept (POC) method helps us share knowledge, explore new technologies, and present a concrete idea. A POC tests a design or technology idea. Its main goal is to show our design’s basic functions and confirm its feasibility. We also include safety analysis to meet standards set by bodies like the FDA and CSA.

Beta Prototyping lets us turn a concept into a testable product for user feedback. This feedback guides design and function improvements. It also helps our team gauge the time needed for a final product. Since we center our design on users, industrial product prototyping is vital for advancing production and pinpointing issues. It refines and validates our design direction with better accuracy.

After creating a concept and prototype, we plan for upcoming features and technologies. Future concept development considers upcoming tech, global trends, market changes, and user needs. It might involve basic requirements or new prototypes. Tailored to client needs and the device type, this approach helps businesses adapt to market changes more quickly.

After making a prototype from our concept, we plan ahead for upcoming features and technologies. We consider future tech trends, global shifts, market changes, and what users might need. Depending on the client and device type, this might involve new concepts or prototypes. This approach helps businesses quickly adapt to market changes.

We use our special psycho-aesthetics methodology in our industrial product development process to create emotional ties between products and users. Instead of just focusing on how a product feels, we consider how it makes users feel about themselves. For industrial designs, this means helping workers feel safe and efficient. Our designs aim to reduce risks and speed up tasks. Industrial product experience design emphasizes a product’s aesthetic appeal, structural form, color palette, and tactile experience.

Our proof of concept (POC) method helps us share knowledge, explore new technologies, and present a concrete idea. A POC tests a design or technology idea. Its main goal is to show our design’s basic functions and confirm its feasibility. We also include safety analysis to meet standards set by bodies like the FDA and CSA.

Beta Prototyping lets us turn a concept into a testable product for user feedback. This feedback guides design and function improvements. It also helps our team gauge the time needed for a final product. Since we center our design on users, industrial product prototyping is vital for advancing production and pinpointing issues. It refines and validates our design direction with better accuracy.

Industrial products come with specific challenges needing expert engineering. Our experienced team often designs with intricate systems and innovative materials. Using advanced AR/VR and CAD tools, we address these issues early, speeding up the design, prototyping, and production process.

We use a three-phase approach for technology roadmap development. First, we set essential requirements, leadership, and scope. Next, we pinpoint system needs, main technology areas, and alternatives. In the final phase, we refine our roadmap before implementing it. This process ensures we prioritize cost-effective technologies for outstanding results.

After creating a concept and prototype, we plan for upcoming features and technologies. Future concept development considers upcoming tech, global trends, market changes, and user needs. It might involve basic requirements or new prototypes. Tailored to client needs and the device type, this approach helps businesses adapt to market changes more quickly.

After making a prototype from our concept, we plan ahead for upcoming features and technologies. We consider future tech trends, global shifts, market changes, and what users might need. Depending on the client and device type, this might involve new concepts or prototypes. This approach helps businesses quickly adapt to market changes.

Industrial product design focuses on conceptualizing and creating products that are functional, aesthetically pleasing, and manufacturable. It combines art, science, and technology to bring innovative solutions to everyday problems.

While general product design can encompass a broad range of items, from digital assets to physical objects, industrial product design specifically targets mass-produced goods, often involving materials like plastics, metals, and other industrial materials.

A deep understanding of the market helps designers cater to consumer needs, predict trends, and ensure that the product has a competitive edge once launched.

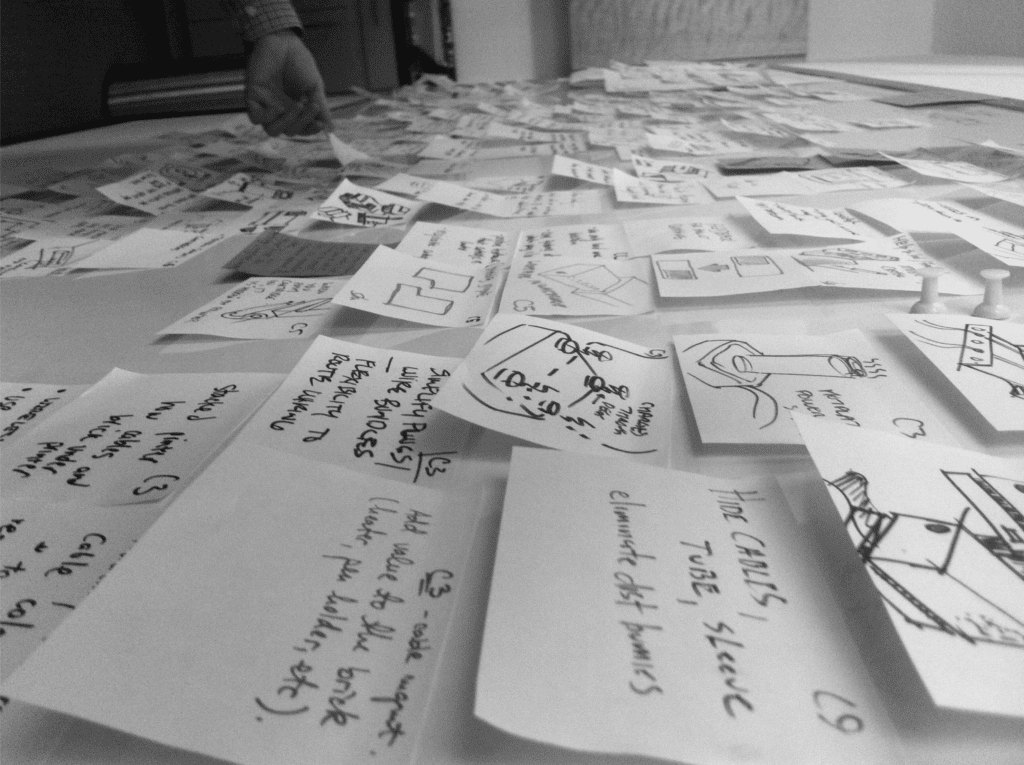

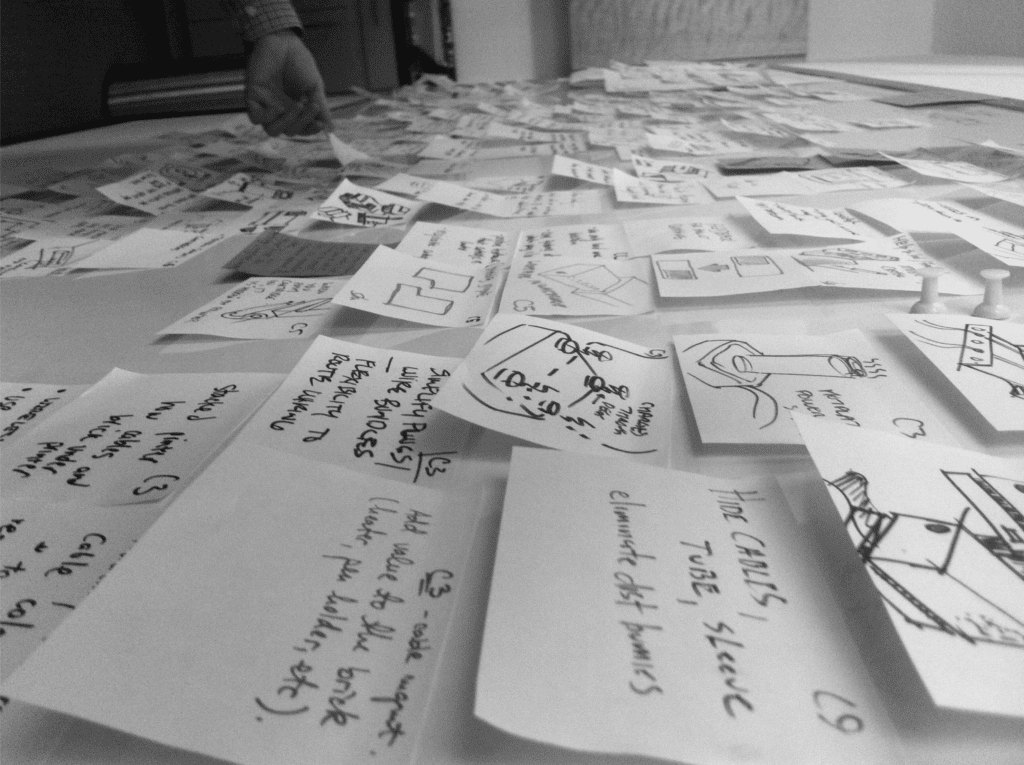

The key stages include research, ideation, prototyping, testing, and manufacturing. Each stage requires careful planning and execution to ensure product success.

Certainly! https://rksdesign.com/work-all/. Our portfolio showcases a range of products we’ve designed, reflecting our commitment to innovation and quality.

Begin by reaching out to our team at https://rksdesign.com/contact/. We’ll discuss your product ideas, market research, and how we can collaborate to bring your vision to life.

Strategy

Welcome to a world of design and innovation

If this is not the case, then click the button below to start it